Pubblicato in News

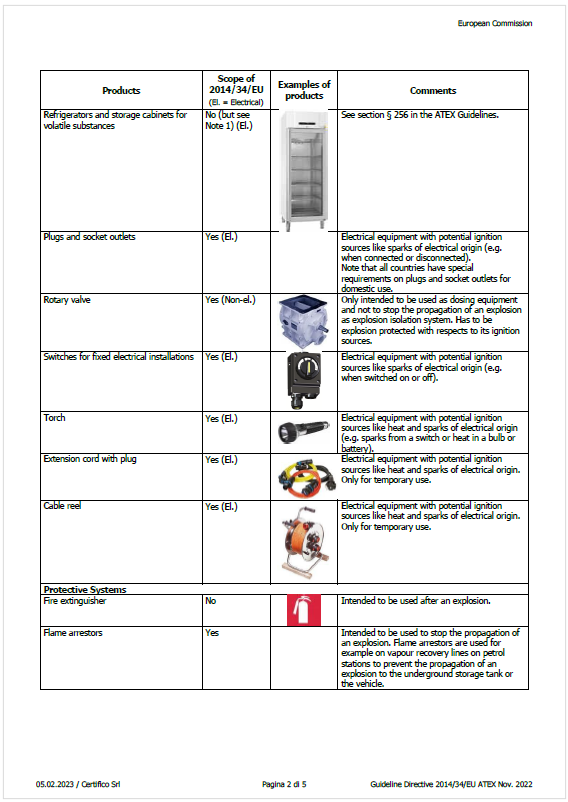

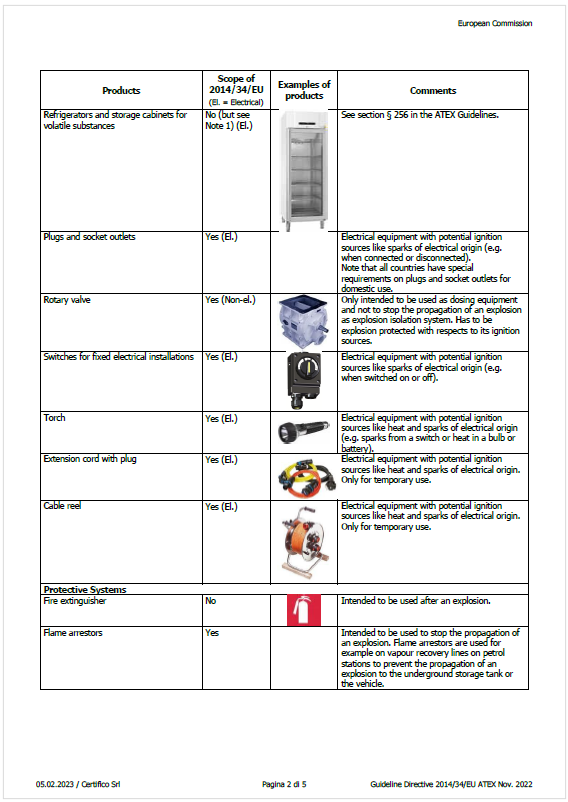

ATEX Prodotti: Borderline list / Nov. 2022

L'elenco (non completo), chiarisce solo alcune domande comuni e fornisce esempi di prodotti all'interno o all'esterno dell'ambito di applicazione della Direttiva ATEX 2014/34/UE.

L'elenco non sostituisce la valutazione dei rischi vitali di ciascun prodotto e, inoltre, delle fonti di accensione e dei pericoli di esplosione devono essere sempre considerati anche quelli relativi all'uso di tutti i prodotti.

...

Fonte EC

- Pubblicato: 05 Febbraio 2023

- Visite: 13573

Pubblicato in News

EN ISO 19353 Prevenzione e Protezione contro il rischio Incendio dei macchinari

Documento sulla norma EN ISO 19353:2019 armonizzata Direttiva macchine 2006/427CE presunzione di conformità al RESS 1.5.6 Incendio.

________

Allegati:

- Documento su EN ISO 19353:2019 + EC 2021

- Documento su EN ISO 19353:2016

________

Documento di approfondimento sui metodi per identificare i pericoli di incendio derivanti dal macchinario e per eseguire la valutazione del rischio in accordo alla norma tecnica EN ISO 19353:2019.

EN ISO 19353:2019 Sicurezza del macchinario - Prevenzione e protezione contro l'incendio

La norma specifica i metodi per identificare i pericoli di incendio derivanti dal macchinario e per eseguire una valutazione del rischio. Essa fornisce i concetti e la metodologia di base delle misure di protezione per la prevenzione e la protezione contro l’incendio da adottare durante la progettazione e la costruzione del macchinario. Le misure considerano l’utilizzo previsto e l’utilizzo improprio ragionevolmente prevedibile della macchina.

La terza edizione annulla e sostituisce la seconda edizione (ISO 19353:2015), che è stata tecnicamente revisionata.

Essa incorpora inoltre l'aggiornamento ISO 19353:2015/DAM 1:2017. Le principali modifiche rispetto all'edizione precedente sono le seguenti:

- le vecchie appendici A e B sono diventate rispettivamente le appendici D e A;

- un esempio di metodologia per la selezione e la qualificazione di un sistema di rilevazione e soppressione degli incendi è stato aggiunto come nuova appendice B;

- la vecchia appendice D è stata migliorata dal punto di vista editoriale ed è diventata l'appendice E;

- è stata eliminata la vecchia appendice E sulle misure di riduzione del rischio di incendio, così come i riferimenti ad essa.

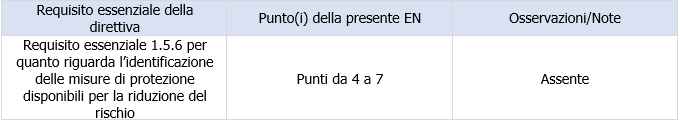

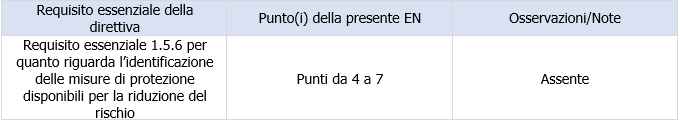

La conformità ai punti normativi della presente norma indicati nel prospetto ZA.1 conferisce, entro i limiti dello scopo e campo di applicazione della presente norma, una presunzione di conformità ai corrispondenti requisiti essenziali di tale direttiva e dei regolamenti EFTA associati.

Prospetto ZA.1 - Corrispondenza tra la presente norma europea e la Direttiva 2006/42/CE

Allegato I Direttiva 2006/42/CE Macchine

[...]RESS 1.5.6. Incendio

La macchina deve essere progettata e costruita in modo da evitare qualsiasi rischio d'incendio o di surriscaldamento provocato dalla macchina stessa o da gas, liquidi, polveri, vapori od altre sostanze, prodotti o utilizzati dalla macchina. [...]

L’incendio provocato dalla macchina crea un grave rischio per le persone e per le cose, in quanto l’incendio può danneggiare o distruggere la macchina e gli impianti ed edifici circostanti. La valutazione del pericolo di incendio comporta l’individuazione e la valutazione di tre elementi essenziali necessari per appiccare un incendio, spesso presentati sotto forma di triangolo (vedi Fig. 2).

Ridurre il rischio di incendio comporta l’adozione di una combinazione di misure rispetto ai tre elementi del triangolo:

- evitare o ridurre l’incorporazione, l’uso o la produzione di materiali o sostanze combustibili. Fra tali misure si annoverano, ad esempio, l’uso di materiali ignifughi nella costruzione della macchina, il contenimento sicuro di liquidi infiammabili, polveri, gas o prodotti dalle macchine e la rimozione sicura di rifiuti combustibili;

− evitare il surriscaldamento della macchina stessa o dei materiali o sostanze utilizzati o prodotti dalla macchina e, nel caso si produca il surriscaldamento, individuarlo e attuare le misure correttive necessarie o segnalarlo all’operatore tramite un allarme prima che la situazione determini il rischio di incendio;

− evitare il contatto fra i materiali o sostanze combustibili e le fonti di innesco quali, ad esempio, le scintille d’origine meccanica o elettrica o le superfici calde;

− ridurre la concentrazione di ossigeno (nella misura in cui ciò non generi un ulteriore rischio per le persone) o evitare la presenza di sostanze ossidanti.

Nel caso in cui il rischio di incendio non possa essere adeguatamente ridotto con queste misure, si devono adottare misure di protezione complementari per limitare gli effetti di un incendio. Tali misure possono comprendere, ad esempio, la schermatura o la copertura di protezione della macchina e l’installazione di sistemi di rilevamento, allarme e/o estinzione degli incendi. Le misure necessarie devono essere definite sulla base della valutazione del rischio di incendio.

Oltre ai requisiti generali di cui al punto 1.5.6, i requisiti supplementari relativi al rischio d’incendio per le macchine mobili sono definiti dal punto 3.5.2; i requisiti supplementari relativi al rischio d’incendio per le macchine destinate ai lavori sotterranei sono definiti dal punto 5.5.

Estratto EN ISO 19353:2019

[...]

5 Strategia di valutazione e riduzione del rischio

5.1 Generalità

La valutazione del rischio di incendio comprende una serie di passaggi logici che consentono l'esame sistematico dei pericoli di incendio secondo le procedure descritte nella ISO 12100. La valutazione del rischio di incendio comprende le seguenti fasi sequenziali:

a) analisi del rischio di incendio, comprendente:

1) determinazione dei limiti del macchinario (vedere punto 5.2);

2) identificazione dei pericoli di incendio (vedere punto 5.3);

3) stima del rischio (vedere punto 5.4);

b) valutazione del rischio.

Quando ritenuto necessario, la valutazione del rischio è seguita dalla riduzione del rischio.

...

Vedi Documento completo

- Pubblicato: 02 Febbraio 2023

- Visite: 11248

Pubblicato in News

Norme armonizzate Direttiva macchine Gennaio 2023: il File CEM

Importa il File CEM in CEM4, e visualizza tutti i titoli delle norme armonizzate per Direttiva macchine aggiornamento Gennaio 2023

Elenco Norme armonizzate Direttiva Macchine 2006/42/CE ad Gennaio 2023, in formato CEM, dei Titoli delle norme armonizzate per la Direttiva Macchine 2006/42/CE aggiornato:

Con il file CEM è possibile tenere sotto controllo in CEM4, nell'Archivio normativa, tutte le Norme armonizzate (n. 829), suddivise per CEN/CENELEC/Tipo A/B/C, consultare, gestire direttamente da CEM4 e commentare le stesse.

Download File CEM Norme armonizzate

Norme armonizzate online

- Pubblicato: 10 Gennaio 2023

- Visite: 12105

Pubblicato in News

Decisione di esecuzione (UE) 2023/69 | Norme armonizzate DM Gennaio 2023

Decisione di esecuzione (UE) 2023/69 della Commissione del 9 gennaio 2023 che modifica la decisione di esecuzione (UE) 2019/436 per quanto riguarda la norma armonizzata per i cicli elettrici a pedalata assistita

GU L 7/27 del 10.1.2023

Entrata in vigore: 10.01.2023

Maggiori info

Elenco Norme armonizzate Direttiva macchine 2006/42/CE Gennaio 2023

- Pubblicato: 10 Gennaio 2023

- Visite: 8583

Pubblicato in News

Nuovo Regolamento macchine 2023: prossima la pubblicazione

ID 18398 | 15 Dicembre 2022 / Fonte: Council and European Parliament - Download scheda

Il Consiglio e il Parlamento europeo concordano nuovi requisiti di sicurezza per i "prodotti macchina".

I negoziatori del Consiglio e del Parlamento europeo hanno raggiunto un accordo provvisorio sul regolamento relativo ai prodotti macchina.

La normativa proposta trasforma la direttiva "macchine" del 2006 in un regolamento.

La direttiva del 2006 è uno dei principali atti legislativi che disciplinano l'armonizzazione dei requisiti essenziali in termini di sicurezza e di tutela della salute applicabili alle macchine a livello dell'UE. Promuove la libera circolazione delle macchine all'interno del mercato unico e garantisce un elevato livello di sicurezza dei lavoratori e dei cittadini dell'UE.

Prodotti macchina che presentano rischi elevati

Il Consiglio e il Parlamento europeo hanno convenuto di dividere in due parti l'elenco delle macchine che presentano rischi elevati soggette alla valutazione obbligatoria della conformità da parte di terzi, come proposto dalla Commissione nell'allegato 1. Secondo l'accordo, solo sei categorie di macchine saranno soggette a tale valutazione obbligatoria della conformità da parte di terzi. Per la maggior parte delle categorie di prodotti, la possibilità di un'autovalutazione della conformità da parte dei fabbricanti è stata così mantenuta e il coinvolgimento degli organismi di valutazione della conformità dipende dalla procedura di valutazione della conformità che i fabbricanti scelgono di applicare.

Dopo un'attenta valutazione e previa consultazione delle parti interessate, la Commissione europea potrà aggiornare tale elenco di prodotti, che devono essere valutati da un organismo di valutazione della conformità a causa della loro complessità e dei potenziali rischi che possono comportare. Ciò assicurerà un equilibrio tra la necessità di garantire il massimo livello di sicurezza e la necessità di evitare di imporre oneri sproporzionati all'industria dell'UE.

Documentazione digitale

Il regolamento trova un giusto equilibrio tra la documentazione digitale e la documentazione cartacea. Ciò significa che i colegislatori hanno convenuto in linea di principio che:

- le istruzioni digitali saranno l'opzione predefinita

- le istruzioni cartacee rimarranno un'opzione al momento dell'acquisto per i clienti che non hanno accesso alla copia digitale

- le informazioni di base relative alla sicurezza dovranno essere fornite con ogni prodotto

Ambito di applicazione

Per garantire la certezza del diritto, i colegislatori hanno deciso di chiarire l'ambito di applicazione e le definizioni proposte dalla Commissione europea. In particolare, hanno convenuto di non escludere i veicoli di piccole dimensioni utilizzati per il trasporto personale e i veicoli elettrici leggeri come gli scooter elettrici e le biciclette elettriche, in quanto sono ampiamente utilizzati e potrebbero essere potenzialmente pericolosi per i loro utilizzatori.

Prossime tappe

L'accordo provvisorio raggiunto oggi deve essere approvato dal Consiglio e dal Parlamento europeo. Una volta completate le fasi formali dell'adozione, gli Stati membri disporranno di 42 mesi per applicare le norme del regolamento.

- Pubblicato: 17 Dicembre 2022

- Visite: 7133